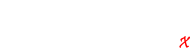

In July, on the yellow coast, the water was rough, with rows of 100-meter-high white fans swaying in the wind. The underwater undercurrent is turbulent, and the huge fan pile is directly inserted into the seabed. A yellow square robot is attached to the fan pile to complete another underwater inspection.

At the beginning of July, the reporter learned from Nantong University that the intelligent underwater maintenance robot integrating target recognition, surface cleaning, nondestructive testing and wet welding was successfully developed in the Institute of Electrical Engineering, providing a new direction for the future maintenance work of offshore engineering enterprises.

No one cares about jobs with a monthly salary of 200000 yuan.

In the vast sea, there are many ships shuttle every day. Above the water, these ships ride the wind and waves, and are majestic; Below the water surface, various hidden dangers lurk in the darkness: hull welding cracks and seawater erosion damage... These small problems often mean endless trouble.

What if these problems occur? The most direct way is to pull the ship into the dock for maintenance. However, this method is obviously not applicable to the urgent problems encountered by ships during navigation. Therefore, people want to repair ships underwater. In 1802, a scholar named Humphrey discovered that the electric arc could burn continuously underwater, which created the possibility for underwater welding.

After years of development, underwater welding has formed three main methods: dry method, wet method and local dry method. Among them, wet welding is the three most widely used technologies, but its disadvantage is that water has poor conductivity and safety.

At present, the realization of underwater welding still depends on the manpower at this stage. Welding itself is a hard work, let alone underwater welding. Its difficulty is self-evident. Workers usually need professional diving training. Before launching, welding rod welding machine, diving helmet, diving suit, lead belt, air compressor, oxygen cylinder, interphone, etc. shall be equipped. Under water, they will not only face the challenge of high water pressure and temperature, but also become blind if the water is dirty.

In December 2019, as a student of Nantong University, Yan Chunkai followed his tutor to learn about the inconvenience of underwater manual welding of Nantong Kaisha Island marine engineering enterprises. Few professionals in the industry can carry out underwater maintenance. According to the data released by the China Classification Association this year, no more than 150 people in China hold NDT underwater welding certificates, resulting in a huge gap in human resources in the ship maintenance industry. Even with a monthly salary of 200000, few people can do it and are willing to do it. Yan Chunkai sighed.

In the face of the severe reality of the industry and the needs of enterprises, Yan Chunkai, under the guidance of teachers, formed a student scientific research team, proposed solutions, designed and developed a robot that can replace human water maintenance.

Many innovations help underwater independent maintenance

With this idea, the team members first investigated the underwater maintenance robots on the market. They found that underwater maintenance equipment that can integrate detection and welding technology into China is an important research direction in the industry, which is difficult and has broad market prospects.

Since February 2020, the team has been engaged in the research and development of underwater autonomous maintenance robots.

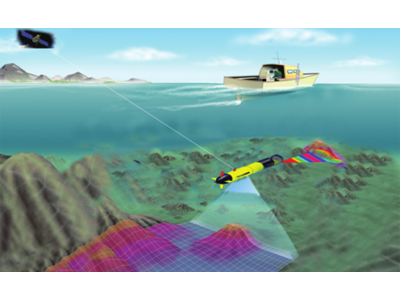

The first step of underwater robot operation is to identify the target. According to the picture principle and a priori mechanism, the system divides the submarine line and the target structural components in order to achieve rough positioning.

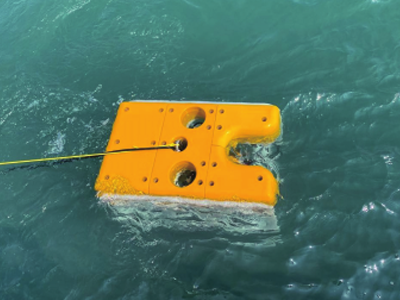

"We once went to Jiangsu Offshore Longyuan Wind Power Generation Co., Ltd. (hereinafter referred to as Longyuan) for field investigation, and found that the water on the seabed was relatively turbid, which directly affected the underwater visibility," Yan Chunkai said. In order to solve this problem, the team used sonar to enhance the acoustic signal on the basis of the original visual recognition, and added auxiliary light sources and polarizers on the machine, and also enhanced the image in the later stage.

Due to long-term immersion, marine organisms are attached to the surface of wind power pile foundation and ship bottom plate. After target identification, the surface needs to be cleaned with high-pressure water jet, and then NDT. At first, the team tried to use a single ultrasonic technology for testing, but the effect was not good. Later, they combined ultrasonic and visual detection to effectively improve the detection accuracy.

After repair, welding is required. In practical operation, underwater visibility is very low, so underwater welding is often very dependent on experience. The worker holds the welding rod and welding machine in one hand and independently controls the welding angle and strength. If they are not careful, the gloves will burn.

During the research and development of the intelligent underwater repair robot, the team uses structured light to enhance the weld characteristics, so that the camera can quickly find defects, and conduct welding operations after offline weld tracking.

Due to the relatively complicated operation, we spent nearly a year on wet welding. Yan Chunkai said. Through continuous trial and error deduction, the team finally overcame the difficulties of underwater welding repair and realized stable welding operation with water depth less than 5 meters.

It is expected to be applied in more scenarios

In the Challenge Cup National Undergraduate Science and Technology Academic Competition in May this year, the intelligent underwater maintenance robot stood out in 706 projects, won the special award of Jiangsu Province, and was shortlisted in the national competition. Due to the poor operation stability of the first generation of equipment, the team members followed the experts' suggestions, improved and upgraded the first generation of equipment, mainly designed adsorption and fixation devices for the maintenance of offshore wind power pile foundation.

When the robot works underwater, the water flow has a great impact. At first, we designed two arms to fix the robot on the wind power pile through magnetic adsorption. Through experiments, it is found that the stability needs to be improved. Therefore, an arm is added under the robot, and the three arms are designed to stretch forward and backward. The triangular structure makes the robot more stable. Yang Hui, a teacher of Nantong University, said.

Compared with the first generation of robots, the improved second generation of robots has made a great improvement. Out of the laboratory, can it bring surprises to offshore enterprises in the actual maintenance work?

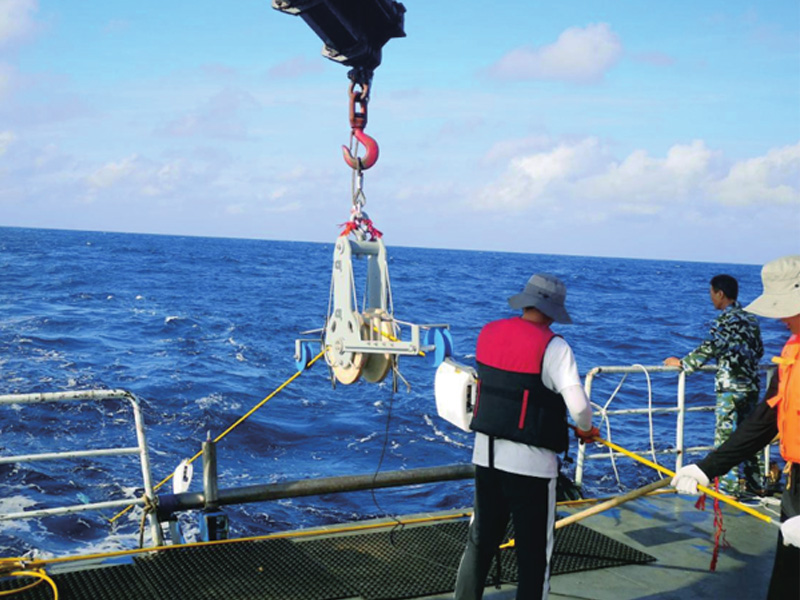

Yang Hui told reporters that after the successful development of the intelligent underwater maintenance robot, they immediately cooperated with enterprises to test the performance of the robot.

During the Longyuan investigation, Yang Hui learned that the company's maintenance personnel did not have underwater maintenance qualifications and could not regularly repair the underwater part, so they had to passively wait for the problem of the wind power pile and shut down the wind turbine unit for maintenance. After cooperating with Longyuan, the team's intelligent underwater maintenance robot helped Longyuan carry out underwater inspection of offshore wind power pile foundation and found many slight corrosion.

In the first half of this year, the team cooperated with the Nantong Branch of Dalian COSCO Shipping Marine Engineering Technology Co., Ltd. to repair 10000 tons of ships, which greatly improved the repair efficiency and played an important role in the repair of ship side panels.

The offshore engineering industry involves oil, natural gas, wind power and other fields, and its impact on human social and economic life is more and more extensive and in-depth. The successful application of AI in the shipbuilding industry can effectively promote the high-quality development of the marine engineering equipment industry. At present, the equipment service objects are mainly for ship hull and offshore wind power piles, which are expected to expand to nuclear power plant towers and other scenarios in the future. Yang Hui said.